3D Printing

3D printing

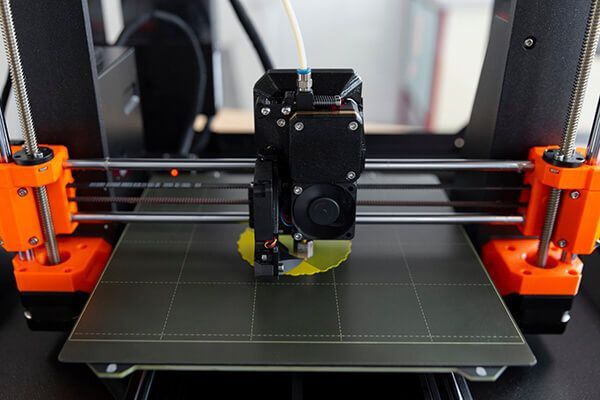

serves as a key tool in the world of product development, especially in the prototype development and testing process. It allows designers, engineers, and entrepreneurs to easily and quickly move from the idea stage to the tangible product stage, assessing the feasibility of the idea. This method/technology does not replace mass production but is used only in the development process.

Today, printing methods give designers, engineers, entrepreneurs, companies, and inventors endless possibilities in a variety of materials and production methods based on 3D printing: plastics and thermoplastics, various metals, chocolate, concrete, glass and resins, composite materials, gold and silver, and the use of bioprinting to print tissues and organs from biological materials containing living cells for the medical field, as well as parts made of stainless steel for heavy industry, defense, aviation, and space. Other materials include transparent and milky materials, flexible and soft materials, and more.

This method of production has several advantages:

- Fast prototyping: 3D printing allows prototyping relatively quickly, reducing development time and costs associated with ordering traditionally produced parts. You can easily print multiple versions of the product, test them, make improvements, and reprint. What’s more, in 3D, on a computer screen, things look and feel differently than parts that can be felt, tested, and experimented with by hand.

- Cost savings: In the past, prototyping was especially expensive because custom tools and templates were needed. Today, prototypes can be printed at a relatively low cost, without the need for complex production tools. This reduces development risks and allows for more experimentation and improvements.

- Personalization and design innovation: 3D printing gives you more design freedom than traditional manufacturing methods. Designers can create custom products or parts with complex geometric structures that are difficult or impossible to produce using conventional technologies like cutting or casting.

- Functionality and compatibility testing: With 3D printing, you can test the suitability of a product to its needs and usage requirements before moving to mass production. This allows you to test the durability, functionality, and aesthetics of the printed product, reducing the risk of breakdowns later on.

- Shorten development times: 3D printing significantly shortens the development cycle of new products by allowing changes and adjustments to be made quickly between different prototypes.

In conclusion,

3D printing makes the product development process more efficient, cheaper, and more flexible, while enabling customization, design innovation, and shorter development times.